SAIREM microwave technology against germs and mould

- Publicado el 06 de Junio de 2023

SAIREM, specialised in industrial microwave (MW) and radio frequency (RF) technologies, has developed a 100 % electric application that replaces conventional solutions such as hot air or steam for combating germs or moulds in food. The gentle process based on MW and RF technology preserves the quality and organoleptic properties of the products and can be used for variousfoods with low water content.

Foodstuffs with low water content, e.g., flour, cereals, lentils, beans, spices, mushrooms, cocoa beans, nuts, seeds, milk powder and more, which are used as an ingredient in food or finished products, must be reliably protected from contamination by microorganisms such as moulds, salmonella, and other bacteria. A safe method for decontamination and sterilisation is heat treatment, the application of which must be precisely coordinated: If the temperature is too low, no effective decontamination will take place. On the other hand, if the temperature is too high, the organoleptic properties of the product will be affected. SAIREM's microwave (MW) and high-frequency (HF) solutions offer an equally effective, gentle, and efficient solution for the sterilisation and disinfestation of dried foods and ingredients.

During the processes developed by SAIREM, the microwave or highfrequency field acts briefly on the product in a temperature controlled chamber and performs homogeneous heating within a very short time. The Temperature intensity of the field and process duration are individually adapted to the application or the product one of SAIREM's core competences. Volumetric heating under precise temperature control guarantees uniform and complete inactivation of salmonellae and a radical reduction of moulds.

The short processing time means that the organoleptic properties of the product are preserved, a significant reduction in the number of contaminating species results in an extension of the shelf life of the product. In this way, the safety and quality of the food can be optimised in equal measure.

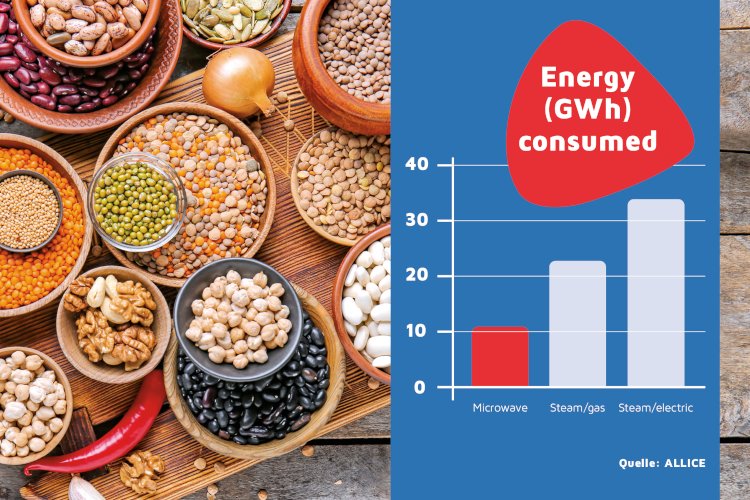

SAIREM's ultramodern, flexible, and modular equipment carry out decontamination in an automatic, rapid, and precisely reproducible process that can seamlessly tracked. The products pass through the machines in batches or in a continuous process (tunnel solution). The automated process can be easily integrated into existing lines and is therefore Industry 4.0-compatible. The decontamination process can be carried out on various types of packaging. e.g., plastic, glass, paper, thermoformed packaging, bags and more. The fully electric solutions operate with moderate power consumption. Thanks to their compact design, the machines are particularly space-saving. They are designed to be extremely user friendly and allow for easy loading and unloading. Apart from daily cleaning, only minimal maintenance is required. All hygiene standards are fully met. The process meets the requirements to produce organic products.